Fujitsu Ten SP-1300A Cassette Repair

This thing took me forever to repair. Firstly finding a manual for this thing was next to impossible. I finally spied a picture of one on an old forum and luckily got hold of the person that had posted it. He graciously sent me the manual that allowed me to repair it and the radio that goes with it. Thank you so much A.J.

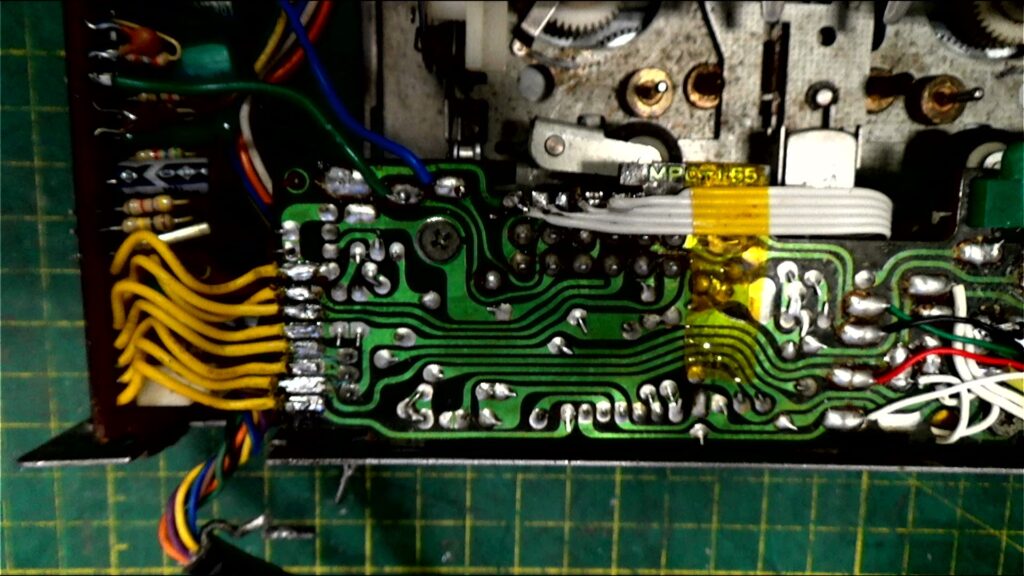

First I had to fix some broken wiring and a flex ribbon from the head to the amp board and the flat cable that connected the two boards together.

There were a few bad caps broken solder joints as well.

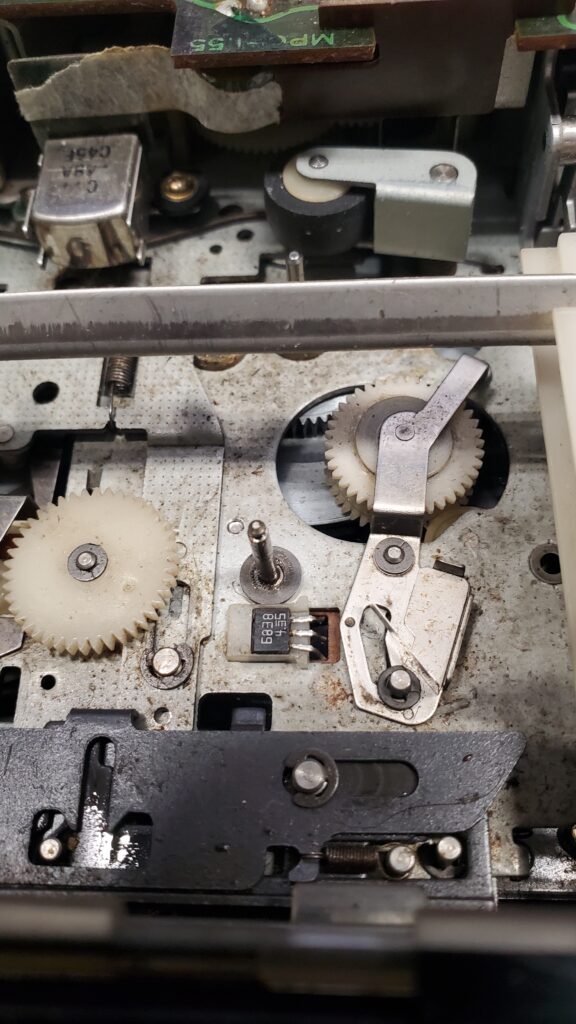

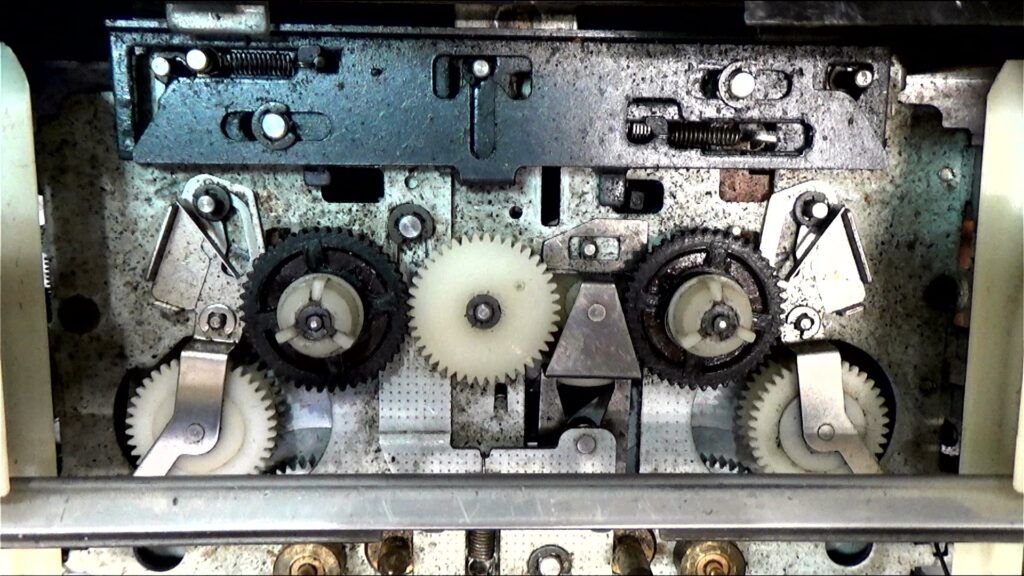

With all the electrical stuff fixed I turned my attention to the broken gears.

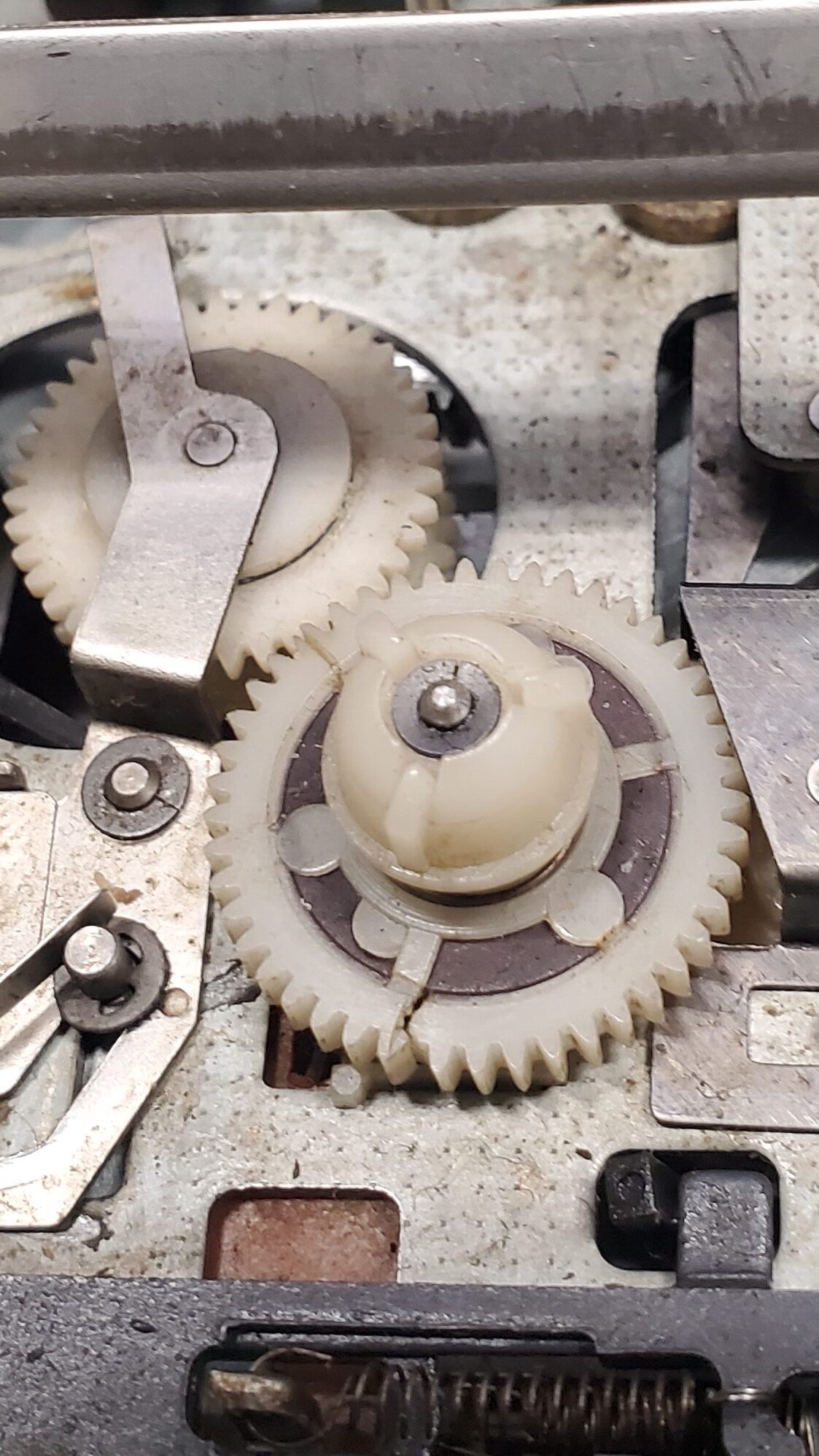

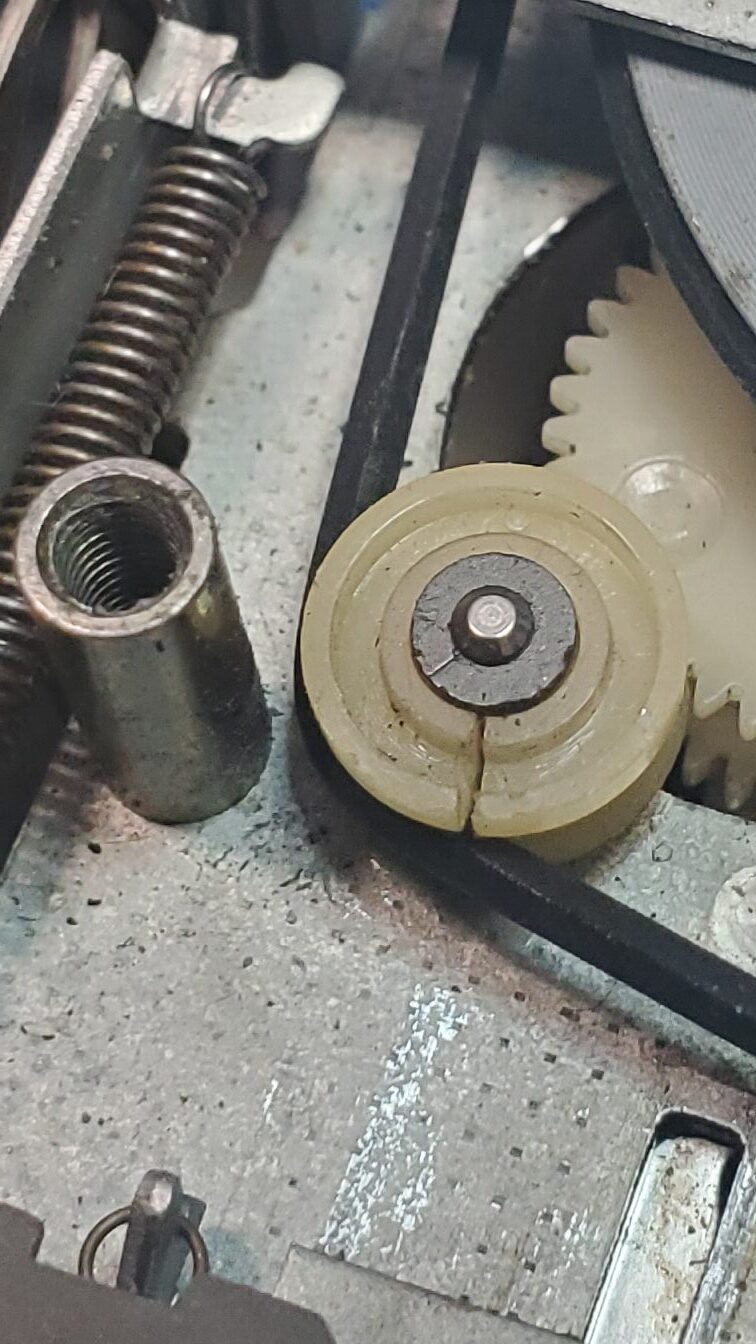

These things split because the plastic and the metalized magnet used to tell the cassette that the take-up reel is turning by passing the poles over a hall effect transistor/IC, expand and contract at different rates.

Since this part of a car stereo setup the temperature differences can be pretty great. Think of how hot is it gets in a parked car in the summer then you turn on the air conditioner. 120F to 70F is quite a change. Do that for 40 years! This is out a 1985 Toyota Celica.

Anyway I messed around for days on Tinkercad and SCad to design a new gear for my 3d printer. I have an Ender 3D Pro and quickly found out that the stock controller board just couldn’t handle this fine of a print so I got an updated board, $50. There are 45 teeth on the thing. Hence a lot of failures.

I started with just a gear with no center and printed the center piece individually. That just never worked out and finally settled on a one piece design but that came with problems too. I had to fool the printer and tell it that it had a 0.3mm nozzle because if I didn’t it would not print the center tall piece at all. That piece has a wall thickness of less than .2mm so I had to print it with a smaller hole in the center and drill it out, very carefully, before it would go over the spindle. Touchy.

The coin magnet fits inside the gear from the bottom where is can pass over the sensor. The tolerances here are pretty tight. The original gear had the magnet press fitted into the plastic. In my opinion that was a mistake. No room for expansion at all. I had to superglue mine in there. The magnet can not stick down below the bottom of the magnet. Much careful sanding and testing. Here is what it looks like now

These gears weren’t the only split things in here.

All four of the pulleys that the belt that drives the head launch, take-up reels and torque pulley were split. That meant that the plastic pulley would eventually ride down the brass insert and come in contact with the fast forward gear and stop the whole thing. I can not print these, too small. They have a brass insert inside that causes the same expanding problem. I finally just made up some epoxy and coated the inside of the gear with a very small amount and let it harden. That seemed to work. Nylon is very hard to glue to, no warranty folks.

This repair took weeks off and on. I would regularly set it aside before I threw it against the wall . I wouldn’t do this normally but it is part of a car restoration and the owner wanted everything to work and be original.

If anybody wants the STL file for the main gear leave a comment and I can email it to you. It will still take a bit of sanding and prepping but since I am sure there is no other place on earth to pick these up and just about every one of the originals is cracked it could be worth the time and effort.

And now for something completely different….

Hi ,

I have the same tape deck with exactly the same broken gears.

Now, is it possible that you could sell me a set of those gears?

It would be greatly appreciated. It is a very nice tape deck.

Thanks much!

email: jenno@q.com

Hi there,

could you sell me a set of the gears? Mine are broken just the same.

Thanks much!

Sorry guys. I do NOT get anything as far as notifications from here. Please contact me at

aervblog@gmail.com

I will gladly share the stl for free.